AUTOMATIC WHEEL BALANCER WITH LCD SCREEN

US-898

The US-898 automatic wheel balancer will be a precise, efficient and fast worker in your daily operation. The SERINI brand guarantees you an outstanding quality and accurate operation. The device can be used in 16 different languages with the rotary knob and the easy-to-use interface management facilitates the change between different functions which serves convenient use. Different sensors and gauges make automatic measurement process more precise.

FEATURES

Multi-language interface and LCD screen

The high quality graphic LCD screen which is similar as a computer’s monitor displays each workflow in high resolution and legibility and facilitates data entry and menu system management. There are 16 languages available as a standard feature.

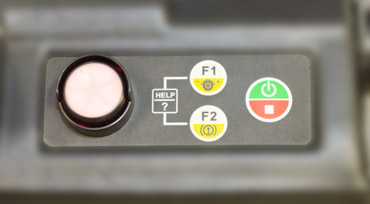

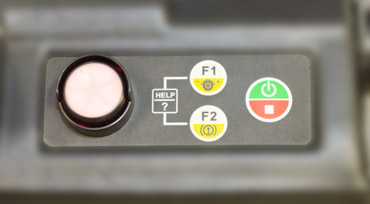

Rotary control interface

Fast-to-learn and extremely handy, precise positioning allows you to use the rotary knob for ease of use. Its positioning is exactly at the height of the user's hand, so it is easy to operate without effort.

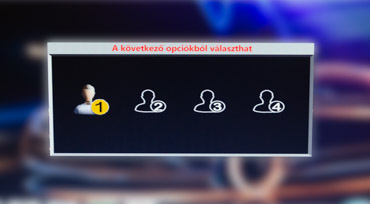

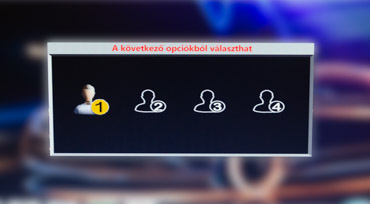

Multi user management

Thanks to the user profiles, all settings can be tailored to the needs of individual workers, thus saving significant working time. You do not need to reset the device between each shift. The device stores the hours of operation, weight used, etc., per user which can be retrieved later.

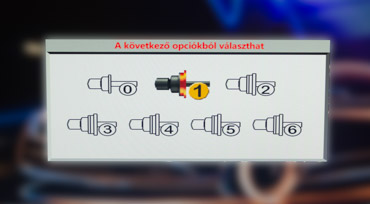

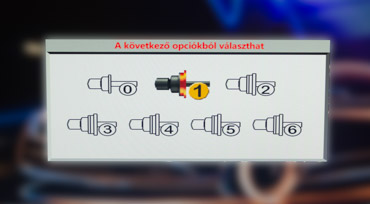

Optional adaptors

The wheel balancer can store data for 6 optional adapters. This allows you to quickly retrieve stored data when using each adapter. Switching times between individual wheel types are shortened, productivity increases and working time is reduced.

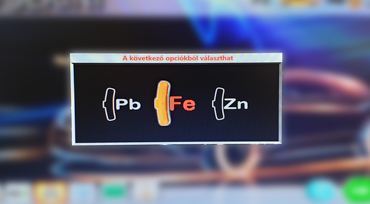

Weight type management

The device is suitable for handling 3 different weight type, namely iron (Fe), lead (Pb) or zinc (Zn). The user can switch between the weights at any stage of the workflow with a simple push of a button. The change in the settings is automatically saved.

LED light

The assist lights placed around the balancing shaft enable better visibility and help when placing the sticking weights or cleaning the surface inside the rim.

Weight placement with laser

The laser indicator placed at 12 o'clock to 6 o'clock makes the placement of the sticking weight inside the wheel hub easier no matter if it is alloy or steel rim.

Ultrasonic gauge

There is no need for manual measurement of width anymore because the ultrasonic gauge does it automatically. It measures the distance automatically when the wheel cover is lowered.

The high quality graphic LCD screen which is similar as a computer’s monitor displays each workflow in high resolution and legibility and facilitates data entry and menu system management. There are 16 languages available as a standard feature.

The high quality graphic LCD screen which is similar as a computer’s monitor displays each workflow in high resolution and legibility and facilitates data entry and menu system management. There are 16 languages available as a standard feature.  Fast-to-learn and extremely handy, precise positioning allows you to use the rotary knob for ease of use. Its positioning is exactly at the height of the user's hand, so it is easy to operate without effort.

Fast-to-learn and extremely handy, precise positioning allows you to use the rotary knob for ease of use. Its positioning is exactly at the height of the user's hand, so it is easy to operate without effort.  Thanks to the user profiles, all settings can be tailored to the needs of individual workers, thus saving significant working time. You do not need to reset the device between each shift. The device stores the hours of operation, weight used, etc., per user which can be retrieved later.

Thanks to the user profiles, all settings can be tailored to the needs of individual workers, thus saving significant working time. You do not need to reset the device between each shift. The device stores the hours of operation, weight used, etc., per user which can be retrieved later.  The wheel balancer can store data for 6 optional adapters. This allows you to quickly retrieve stored data when using each adapter. Switching times between individual wheel types are shortened, productivity increases and working time is reduced.

The wheel balancer can store data for 6 optional adapters. This allows you to quickly retrieve stored data when using each adapter. Switching times between individual wheel types are shortened, productivity increases and working time is reduced.  The device is suitable for handling 3 different weight type, namely iron (Fe), lead (Pb) or zinc (Zn). The user can switch between the weights at any stage of the workflow with a simple push of a button. The change in the settings is automatically saved.

The device is suitable for handling 3 different weight type, namely iron (Fe), lead (Pb) or zinc (Zn). The user can switch between the weights at any stage of the workflow with a simple push of a button. The change in the settings is automatically saved.  The assist lights placed around the balancing shaft enable better visibility and help when placing the sticking weights or cleaning the surface inside the rim.

The assist lights placed around the balancing shaft enable better visibility and help when placing the sticking weights or cleaning the surface inside the rim.  The laser indicator placed at 12 o'clock to 6 o'clock makes the placement of the sticking weight inside the wheel hub easier no matter if it is alloy or steel rim.

The laser indicator placed at 12 o'clock to 6 o'clock makes the placement of the sticking weight inside the wheel hub easier no matter if it is alloy or steel rim.  There is no need for manual measurement of width anymore because the ultrasonic gauge does it automatically. It measures the distance automatically when the wheel cover is lowered.

There is no need for manual measurement of width anymore because the ultrasonic gauge does it automatically. It measures the distance automatically when the wheel cover is lowered. TECHNICAL SPECIFICATIONS

| Rim width | 10"-32" |

| Rim diameter | 1.5"-25" |

| Max wheel weight | 70 kg |

| Read-out accuracy | 1 g |

| Cycle time | < 6s |

| Spinning speed (rpm) | < 160 |

| Power supply | 230V |

Automatic

Wheel Balancer

US-898

Top features that make working easier:

- The wheel balancer automatically load all parameters, not need any calibration

- 19" LCD display

- Wheel hub check

- Optimized automatically bidirectional locating, locking and fixing point braking function, simple to use

- Automatic positioning

- Ultrasonic gauge B

- Laser beam indicating position at 6 and 12 o'clock attaching counterweight

- Self-check & diagnosis function

- Optional motorcycle accessories for motorcycle dynamic balance measurement (US-MAB1, US-MAB2, US-MAB3)

- User-friendly ring-shaped LED light to measuring and attaching process

- Available languages: EN, DE, HU, RO, SI, CZ, SK, HR, IT, RUS, JP, CN, KR, ES

Due to its unique attributes the machine is suitable for balancing all kind of wheels. It can also be used for balancing motorcycle wheels with an optional accessory.

Standard equipment:

- Calibration wheel weight, 100g

- Cone set

- Wheel weight hammer and pliers’ tool

- Quick lock nut

- Low-profile support ring for quick-lock nut

- Plastic cap, bore diameter

- Spherical mirror

- Calibration tool

Optional accessory: Motorcycle adapter

INQUIRE